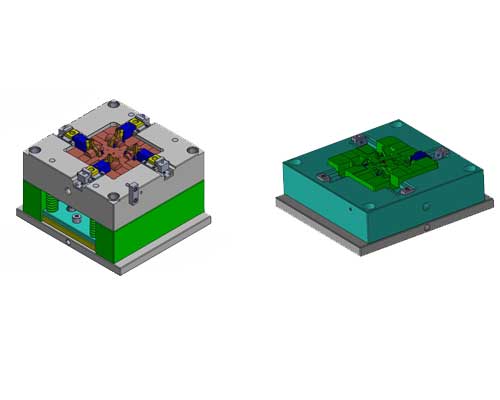

Our in-house tool room activities are focused primarily on the design and development of new moulds for new product development and regular preventive maintenance of existing moulds. Our tool room is well-equipped with multiple VMC and EDM machines and other associated equipment. All the machines are from reputed companies and give the highest quality of output.

The tool room team consists of well qualified and experienced tool room engineers who are ably supported by the rest of the team having experience in various vocational fields. The team has developed various complex multi-cavity hot runner as well as cold runner for domestic as well as export customers.

Our experienced team is equipped with multiple seats of SolidWorks by Dassault Systèmes for tool designing. They analyze the part design and make modifications and recommendations based on product requirements including usage and function. We can also reverse engineer and develop the final part from part samples submitted by the customer.