At Paramjyoti Movers, we believe that our quality certifications such as IATF 16949:2016 and ISO 9001:2015 demonstrate our commitment to provide the best possible parts at the most competitive prices. In addition to the above certifications, we are also a Maruti Suzuki approved “Green Category” supplier. However, our commitment goes beyond certifications. Our team of in-process quality personnel ensure that production is in line with customer quality requirements to the maximum extent possible.

Ensuring quality output is a process that requires coordination between multiple teams. Our incoming quality check team ensures that all raw materials and bought out parts sourced are as per grades and specifications given by the customer. The in-process quality team ensures that the production team is aware about the potential quality defects that can crop up during production and that training about identifying these defects is passed down to the machine operators. In addition to the above, the in-process quality team sees to it that there are multiple checks in place to ensure error free production with minimal rejections. They carry out first piece and last piece approval and pre-dispatch inspection to maintain quality. We are presently in the process of developing a quality lab for validating the critical properties of raw materials used in our production process.

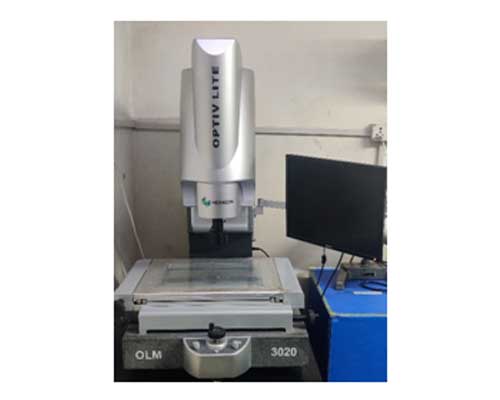

Developing high quality parts requires multiple measurement tools. We have provided our team with a variety of equipment including:

- 1. A Vision Measuring Machine

- 2. A Moisture Analyzer

- 3. Magnifying Glass

- 4. Surface Roughness Tester

- 5. Shore A & D Hardness Testers

- 6. Height Gauge

- 7. Multiple traditional inspection tools such as digital vernier calipers and micrometers